Sichuan's First Natural Gas Power Project Commissioned

2025-12-12 16:23:58 by AIOS

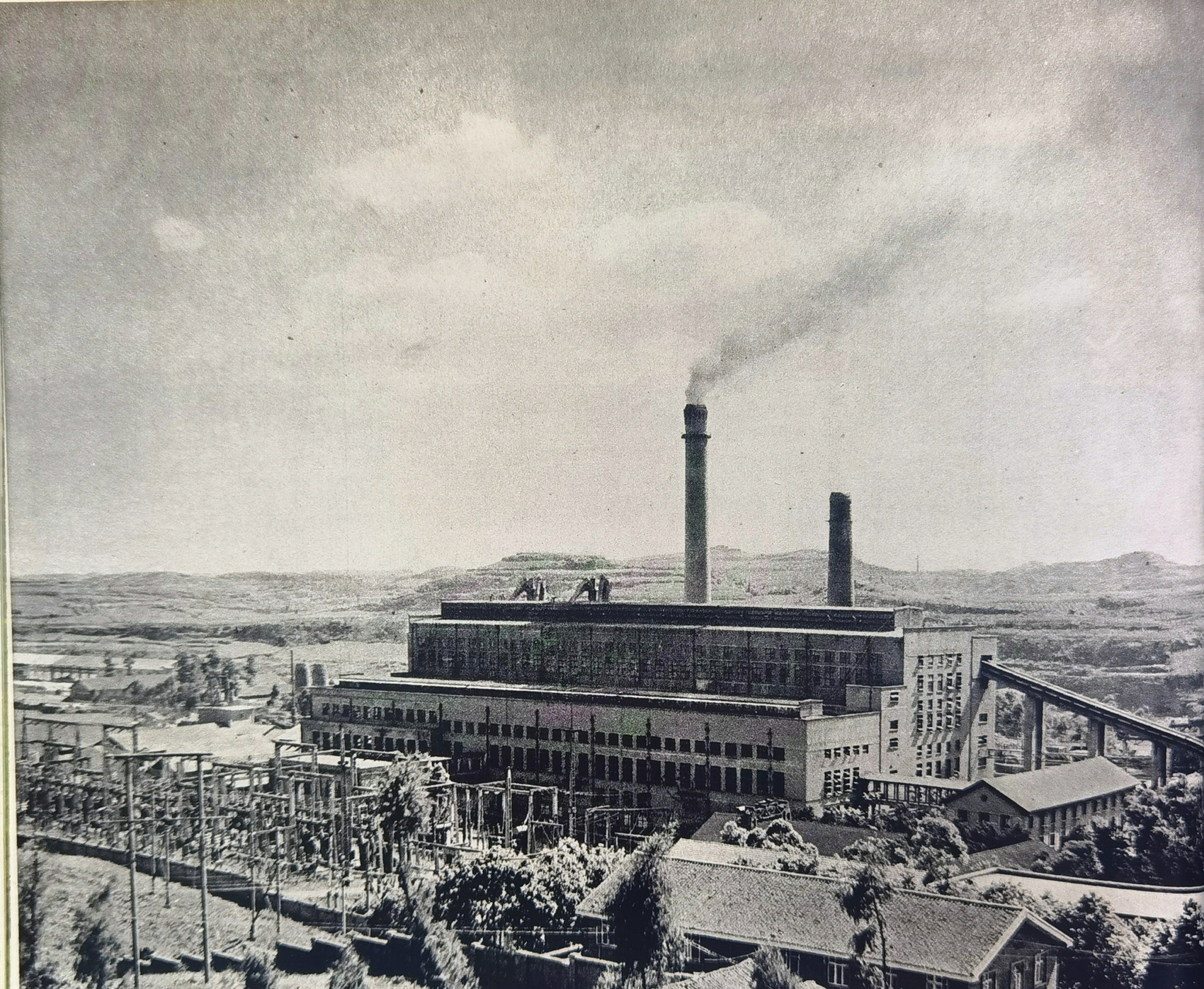

The No. 1 unit of the Sichuan Huadian Neijiang Baima Gas Turbine Project has successfully completed a 168-hour full-load trial operation, marking the formal commissioning of Neijiang's first natural gas power generation project. Over sixty years ago, the first coal-fired unit of the Baima Power Plant went into production. Today, the 'Coal to Gas' project has added new strength to the province's peak-shaving power supply.

Why was Baima, Neijiang chosen as the site? What stories lie behind the project? How will it affect regional development?

In an on-site investigation, reporters found that the plant has retained many old facilities of the Baima Power Plant, such as the pump house and coal transportation tracks. Baima Township has been associated with electricity since the 1950s and 1960s.

The Baima Power Plant was once a well-known power plant in China but was gradually shut down amidst the restructuring of energy sources. In 2013, the world's first 600-megawatt ultra-supercritical circulating fluidized bed boiler went into operation, and in 2025, the gas turbine unit was put into operation, with an annual power generation capacity of up to 2.375 billion kilowatt-hours.

The 'Baima Power Transformation' not only solved the problem of personnel placement but also provided a new solution for local energy supply: one base load power source and one peak-shaving power source, flexibly responding to changes in grid load.

Transitioning from 'ensuring power supply' to 'optimizing power supply', gas-fired power generation has the advantages of rapid start and stop, flexible peak-shaving, and low-carbon emissions, fitting the needs of new energy grid integration and ensuring grid security. The Neijiang Municipal Development and Reform Commission stated that gas-fired power generation plays a crucial role during the summer peak period.

The total investment of the project is 2.14 billion yuan, with an annual power generation capacity that meets the needs of nearly one million households, saving 200,000 tons of standard coal and reducing carbon emissions by 880,000 tons per year. The project is also directly connected to the Weiyuan shale gas pipeline network, extending the industrial chain, achieving efficient conversion of resources, and injecting new momentum into regional industrial upgrading.

【本文部分内容由AI辅助生成,特此声明。The author(s) generated part of the content in this work with the assistance of artificial intelligence (AI), which is hereby declared.】